ATEX Certification and Zone Classifications

31 August 2021

In any working environment, it is crucial that the

appropriate legal health and safety measures are firmly in place to safeguard workforces,

and to ensure that potentially hazardous equipment is fit for purpose and being

used safely.

This is where the implementation of strict legal standards

like ATEX certification and zone classification play a vital role in ensuring

operations run safely.

Here, we explore ATEX certification and zone

classifications, and how ATEX compliant rugged devices protect

operations within hazardous environments.

What is ATEX?

The ATEX directives are a set of two strict pieces of EU legislation

that set out the minimum safety requirements for workplaces and equipment used

in explosive environments.

They came into force on the 1st July 2003 and state that any

equipment used in potentially explosive atmospheres within the EU is required

to comply with the ATEX directive.

The name ATEX derives from the French title of the 94/9/EC

directive (Appareils destinés à être utilisés en ATmosphères EXplosibles).

Any equipment in use before July 2003 can continued to be

used, provided a risk assessment shows it is safe to do so.

What is the purpose of ATEX certification?

ATEX certification ensures that any equipment or protective

system is fit for its intended purpose. It also ensures that adequate

information is supplied with the certification to ensure that any equipment can

be used safely within hazardous environments.

How is ATEX implemented in the UK?

While the ATEX directives is legislation set out by the European

Parliament, by law, they must be embodied into the laws of each EU member. As the

ATEX regulations are already part of UK law, they are not affected by the UK’s

exit from Europe. The legislation covering the ATEX directives are embedded

into the UK’s legal system through the Dangerous Substances and Explosive

Atmosphere Regulations (DSEAR).

The DSEAR

The DSEAR is the UK’s implementation of the European Union’s

ATEX directive into the UK legal system. DSEAR places the ownness on employers

to:

- Reduce or eliminate risks from dangerous

substances in the workplace.

- Identify and control fire, and explosion

hazards, to protect employees, assets and the working environment.

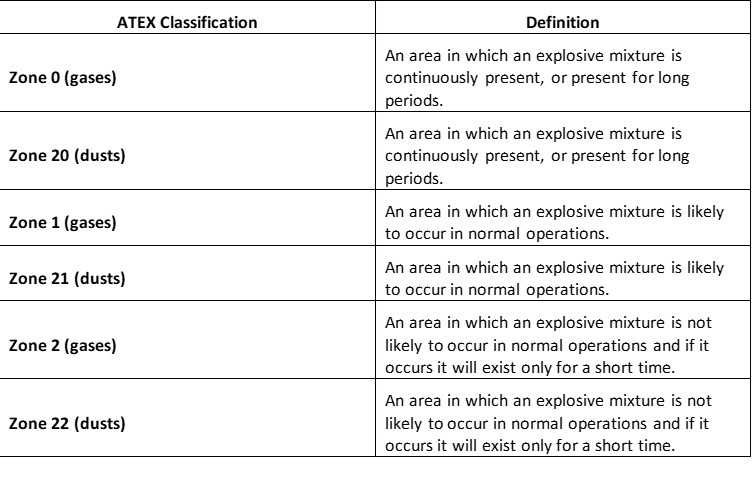

ATEX zone classifications

ATEX uses zone numbers to distinguish between environments with

different levels of danger. The ownness and responsibility lies with the

employer to ensure that their working environments are correctly classified:

ATEX zones 20 and 0 represent the most dangerous workplace

environments.

Zone

classifications and TouchStar

There are several

zone classifications which apply to different working environments. At

TouchStar, our range of specialist devices are suitable for zones 1 and 2.

Zones 1 and 2 are not

prohibitive to the use of rugged mobile computers, in fact there are a several

of our devices that are purpose built for zones 1 and zone 2.

Our zone 2 devices

are suitable for the following industries:

-

Fuel distribution markets (bulk logistics)

-

Hazardous chemical markets requiring rugged

devices

ATEX certified rugged devices

At TouchStar, we understand that when you are working in any

hazardous environment, it is critical that the equipment being used complies with

legal safety standards and keeps operations safe.

Each of our rugged devices are ATEX certified, and all

comply with the protective standards as set out in the ATEX directives.

-

Our wide selection of sophisticated rugged devices,

including the TS3200 boast an array of features which ensure they are ATEX certified:

- Each of our rugged devices have been specially

designed to withstand the demands of potentially explosive atmospheres.

- Not only does their robust design mean they can operate

safely within hazardous environments, but they will deliver high performance

data capture, regardless of the conditions they are used in.

- Our ATEX mobile computers are built to last and

integrate materials including metal alloy chassis, silicon mounted chassis and

polycarbonate plastics.

- Our long-standing relationships with well-known names

in ATEX environments enable us to offer a partnership led approach, full

end-to-end service and post-sales support.

Find out more about our range of ATEX certified rugged

devices here.

Operate safely today with rugged devices from TouchStar

Ensure you are operating safely and complying with ATEX

standards with the help of TouchStar’s rugged mobile devices. To find out more

about how they could benefit your business, get in touch today.

ABOUT THE AUTHOR - PETER MARSH

Peter joined TouchStar (formally Belgravium) in a sales manager role in 2001. Prior to joining the company, Peter held Partner and National Sales Manager roles within the parcel and logistics industries.

In 2011 Peter was promoted to Sales Director and is now actively involved in promoting the value of TouchStar’s Rugged Mobile Computing solutions to the warehouse, logistics, manufacturing and field service industries. When not involved in the business, Peter is a keen and enthusiastic football and cricket fan.