How Are Rugged Devices Tested?

20 October 2021

If you’re considering buying rugged devices for your

business, you want to ensure they’ll stand the test of time and do the job you

need them to do. The testing process is vigorous and is standardised across all

rugged devices. But how are rugged devices tested?

Types of rugged devices

Within rugged devices, there are three levels of ruggedness;

semi-rugged, fully-rugged and ultra-rugged. These levels show how much exposure

a device can endure which is put to the challenge during testing:

- Semi-rugged devices are enhanced versions of off

the shelf hardware meaning they share some components but are better protected.

- Fully rugged devices are designed to work in

extreme conditions and are durable, waterproof, dustproof and resistant to

drops and shocks.

- Ultra-rugged devices are created specifically

for military use which can survive the worst conditions.

Why do rugged devices need to be tested?

Product specifications are incredibly important for all

technology, but especially rugged devices. As they’re used in the most demanding

and potentially hazardous situations, rugged hardware needs to be resilient to

drops, water, dust and shocks. They need to be reliable and not break after the

first knock or drop.

For many businesses, rugged devices are an incredibly

important part of the supply chain and need to be relied upon for the continual

flow of information and data. Any downtime caused by a malfunction or broken

device could cause financial losses due to the disruption to the manufacturing

process or supply chain. Therefore, it's incredibly important that rugged

devices are tested to ensure their level of ruggedness is what the company

needs, and has paid for.

How are rugged devices tested?

Although rugged devices are all created to minimum industry

standards, they are not built the same and must be tested to demonstrate their

durability. Can your chosen device withstand an accidental drop from a

forklift, or being left in a cold environment by accident?

Given the demand on devices, they are tested and measured in

two ways; IP Rating and MIL-STD-810.

IP Ratings

IP Ratings are a common set of testing standards used in the

UK. Developed by the European Committee for Electro Technical Standardization

(CENELEC), IP Ratings, also known as Ingress Protection, provides a standard to

define the levels of sealing effectiveness of an electrical device. The sealings

need to be able to protect the device from foreign materials including water,

dust and dirt which could damage the internal components.

To conduct the IP rating tests, third party laboratories and

specialist equipment is used to ensure each test is conducted in the same way. The

equipment includes immersion tanks, water, dust nozzles and jets.

What do IP Ratings show?

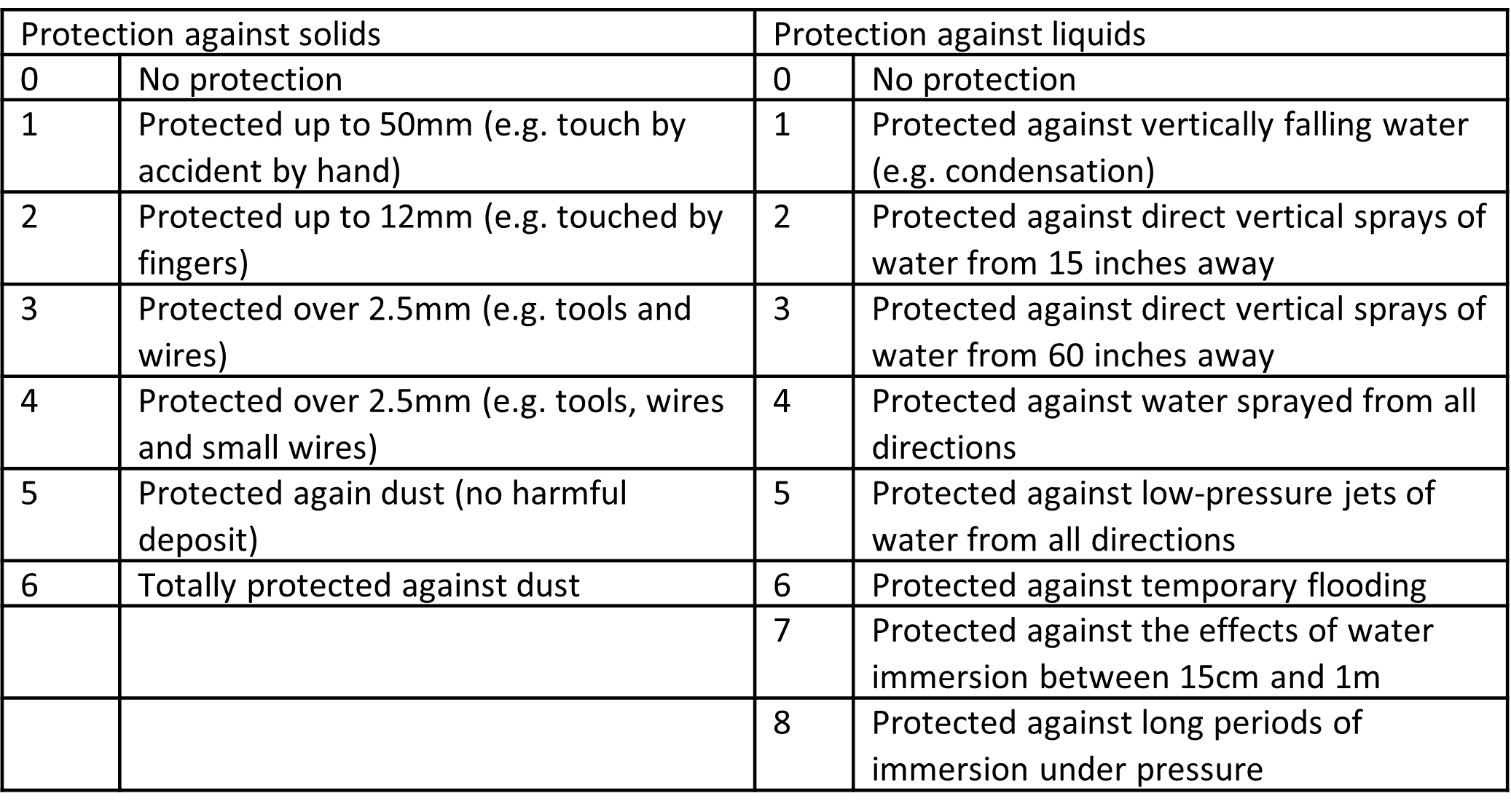

IP Ratings are shown by IP followed by two numbers which

correspond to solid ingress and liquid ingress.

For devices to be considered as fully-rugged, they must

achieve a minimum rating of IP54 which means the device is protected against

dust and has some water resistance. At TouchStar, devices such as the handheld TS8200

and vehicle mount TS3200 have

a rating of IP54.

In industries where higher levels of protection are needed

such as manufacturing or hazardous environments, an IP rating of IP65 or higher

is recommended. This means a device can completely withstand dust, dirt and low-pressure

water, and can also withstand a meter drop.

In construction, an IP rating of IP67 or higher would be

preferable as this would ensure they could withstand a one-meter water submersion

for up to 30 minutes. At TouchStar, our handheld TS5000

device has a rating of IP67.

MIL-STD-810

To conform to MIL-STD-810 standards, devices have to endure

a series of tests created by the US Military. The 29 tests assess how the

technology performs at an optimal level under harsh environments, and are

extremely extensive by covering a range of situations and conditions. They’re

conducted in laboratory conditions and cover changing weather conditions,

pressure changes, drops, shocks, and heavy vibrations.

The MIL-STD-810 standards are often revisited, updated to

reflect changes in technology and demands. In January 2019, the newest

standards were letter H which made some significant changes to the previous

version G. These amends were made to multiple sections including the Test and

Evaluation Master Plan (TEMP), procedures for high temperature testing and

procedural changes to immersion testing.

As this level of testing is not required in the UK, not all

rugged devices are tested against the MIL-STD-810 standards. Therefore it’s

worth checking the specification of any rugged device you’re considering if you

require it to meet US military standards.

Find out more

Here at TouchStar, we offer a range of rugged devices which

has been thoroughly tested to ensure they’re suitable in many different

environments and sectors including logistics and manufacturing. To find out how

they could benefit your business, get in touch today.

ABOUT THE AUTHOR - PETER MARSH

Peter joined TouchStar (formally Belgravium) in a sales manager role in 2001. Prior to joining the company, Peter held Partner and National Sales Manager roles within the parcel and logistics industries.

In 2011 Peter was promoted to Sales Director and is now actively involved in promoting the value of TouchStar’s Rugged Mobile Computing solutions to the warehouse, logistics, manufacturing and field service industries. When not involved in the business, Peter is a keen and enthusiastic football and cricket fan.